The Methane Revolution in Spaceflight: Why So Late?

Leading space companies are increasingly developing methane-powered rockets, as methane unlocks the potential for reusability. This article explores why methane is particularly relevant today.

Issue 116. Subscribers 44,821

As space exploration advances, new rockets are constantly being developed. Over the years, humanity has experimented with various engine types and approaches, yet the drive for innovation continues. We've pushed the limits of traditional expendable rockets and chemical propulsion, prompting the search for more efficient solutions.

One of the most significant shifts in recent rocket technology is the rise of reusability. Falcon 9 demonstrated the effectiveness of this approach, securing a dominant position in the market. Now, reusable rockets have become the industry standard, with vehicles like Starship and New Glenn leading the next generation.

Another emerging trend is the growing interest in methane-powered rockets. But why has methane suddenly become the fuel of choice? In this article, we explore what’s driving this shift and why methane engines are gaining momentum now.

In a previous article, we explained how rockets work. The basic principle is jet propulsion—similar to when you inflate a balloon and let it go. The air rushes out in one direction, and the balloon moves in the opposite direction. Rockets operate the same way: burning fuel is expelled at high speed in one direction, propelling the rocket forward in the other.

By combining different fuel components, engineers can achieve various rocket performance characteristics. In modern rocketry, fuel mixtures are carefully chosen based on specific mission requirements—whether it’s efficiently launching heavy payloads from Earth or enabling long-duration interplanetary travel. Let’s take a closer look at the most commonly used fuel components:

RP-1: A classic and time-tested choice. RP-1 (refined kerosene) combined with liquid oxygen (LOX) offers high density and stability, making it relatively easy to store and handle. This fuel combination has been used in legendary rockets like the Saturn V and Falcon 9. One of RP-1’s key advantages is its compactness, allowing for smaller fuel tanks—a crucial factor in the initial phase of flight, where high thrust is needed while keeping the rocket’s mass as low as possible.

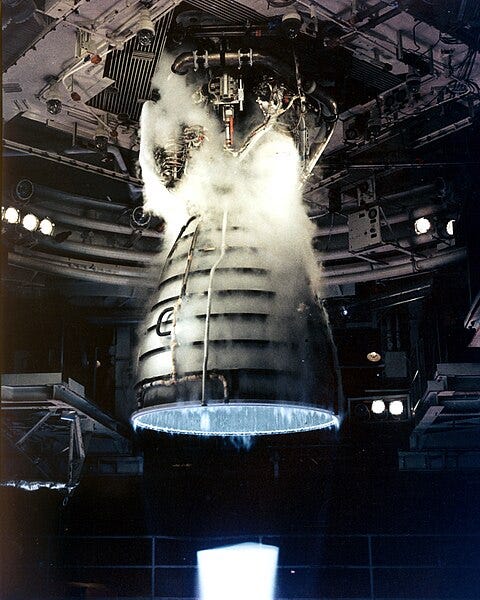

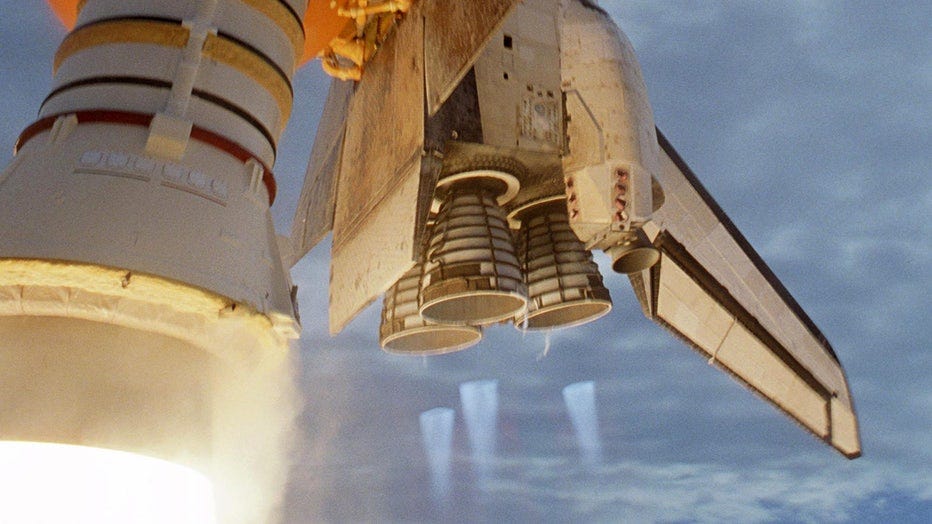

Liquid Hydrogen (LH₂) and Liquid Oxygen (LOX): This combination is used to maximize specific impulse and efficiency, especially in upper stages. While hydrogen offers the highest energy efficiency, its low density and extreme storage requirements (cryogenic temperatures) make it challenging to handle. Despite these complexities, LH₂-powered rockets deliver exceptional performance, making them effective for launching payloads into orbit. This fuel was key to the Space Shuttle’s main engines and is still used in modern launch systems like the SLS and Ariane 5.

Hypergolic Propellants: These are fuel and oxidizer combinations that spontaneously ignite upon contact, eliminating the need for complex ignition systems. This property makes them ideal for applications requiring instant and reliable engine response, such as orbital maneuvers, attitude control, and emergency propulsion. Common hypergolic fuels include hydrazine and its derivatives (monomethylhydrazine or dimethylhydrazine), paired with nitrogen tetroxide (NTO) as the oxidizer. While these propellants are less efficient in terms of specific impulse compared to other options, their dependability and simplicity make them indispensable for spacecraft propulsion and critical mission stages. This fuel has toxic components underneath, which is why it is being abandoned.

And now, let’s talk about the most promising combination—methane and liquid oxygen (LCH₄/LOX). Methane isn’t without its challenges: it requires low temperatures and high-pressure storage. But that’s exactly what modern spaceflight is tackling today.

Each propellant combination is chosen based on mission needs: RP-1’s density and reliability make it ideal for powerful first stages, LH₂’s efficiency shines in high-performance upper stages, and methane is emerging as the key player for the future—powering reusable rockets and interplanetary travel.

Methane as a Prospective Fuel

Methane is used as a fuel and liquid oxygen as an oxidizer. Let's consider the pros of this fuel pairing

1. Optimal Specific Impulse.

A rocket engine is more efficient when it burns fuel as effectively as possible. To measure this efficiency, engineers use specific impulse (Isp), measured in seconds. Simply put, it’s like a rocket’s version of a car’s “miles per gallon” – the higher the number, the better the fuel efficiency per unit of mass.

Specific impulse depends heavily on the type of fuel used. The current champion in efficiency is liquid hydrogen (LH₂), which is why it’s often chosen for upper-stage engines. However, hydrogen’s low density means it requires large, bulky tanks, adding weight and complexity – a challenge engineers always try to minimize.

This is where methane strikes a balance: it offers a higher specific impulse than RP-1 (kerosene) while being denser and easier to store than hydrogen. That makes it an attractive choice for modern rocket designs.

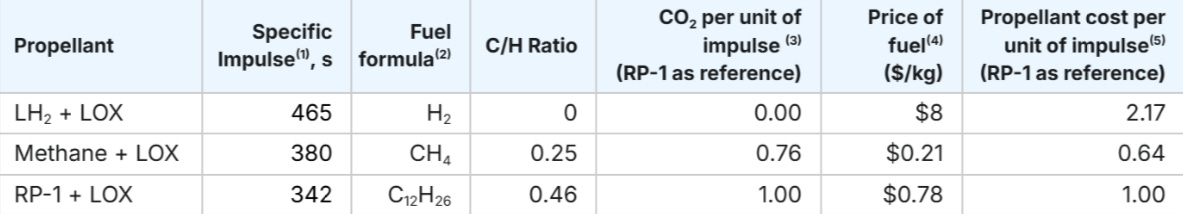

Let us compare the specific impulse values for different fuels:

Liquid hydrogen: 366-452 s (RS-25 engine, Space Shuttle/SLS)

Liquid methane: 330-350 s (Raptor engine, SpaceX)

RP-1 (kerosene): 282-311 s (Merlin engine, SpaceX)

While methane isn’t as efficient as hydrogen, it outperforms kerosene in terms of specific impulse. More importantly, it offers a practical advantage: it requires smaller tanks than hydrogen, reducing the overall size and weight of the rocket’s structure. Compared to a similar kerosene-based design, using methane would only require a 25-30% increase in tank volume—a manageable trade-off, especially with modern composite materials. Additionally, methane’s storage temperature is higher than liquid hydrogen’s, making it easier to handle and less prone to fuel loss due to boil-off.

Сleaner Burning.

Methane isn’t just any hydrocarbon—it’s the simplest one. Its molecule consists of one carbon atom and four hydrogen atoms, whereas RP-1 (kerosene) is a mixture of hydrocarbons with longer carbon chains, some containing up to 20 carbon atoms.

This difference in molecular structure has a big impact on engine performance and reusability. RP-1 doesn’t burn completely, leading to the formation of soot and solid carbon deposits (coke) inside the engine. These white-hot particles give Falcon 9’s exhaust its bright, fiery glow—unlike the nearly transparent exhaust of methane-powered rockets like Starship. The problem? Coke buildup reduces engine efficiency and reliability. In reusable rockets, it also means more maintenance—for example, Falcon 9’s first stage requires extensive cleaning after each flight to remove RP-1 residue.

Methane, on the other hand, burns almost completely, leaving no soot. This improves engine performance, increases reliability, and makes the rocket easier to maintain for the next launch, making it more economical to operate. This is super-important for the first stages of reusable rockets and is a key advantage right now.

Can be Generated on Mars.

All of us in the space industry dream of traveling to other planets. NASA and China are planning missions to the Moon, and Elon Musk is aiming for Mars. That said, flying to planets, especially Mars, requires a lot of fuel to get the craft up to speed and back to Earth. Taking all the fuel needed for such a long trip would be extremely difficult. Instead, scientists want to produce fuel directly on the planets, and that's where another key advantage of liquid methane comes in.

Theoretically, methane can be produced on Mars. The planet's atmosphere is 95% carbon dioxide, and there is a significant amount of water below the surface and at the poles. Using a process called the Sabatier reaction, these resources could be utilized to produce methane.

If methane production can be established on Mars, it will not only make interplanetary travel more realistic but also sustainable. If successful, this project could transform Mars into a base for further research.

Simpler to Manufacture.

Methane is a simple and inexpensive fuel that is widely used on Earth. While liquid methane requires some refinement to remove unwanted compounds and refrigeration to create the final cryogenic propellant, the process is much simpler and cheaper compared to the complex steps involved in producing RP-1 propellant or liquid hydrogen—both of which are more expensive. Despite hydrogen’s higher efficiency, which helps reduce the mass of expensive fuel required, methane still proves significantly cheaper overall in terms of propellant cost per unit of impulse (see the table below). This is an important factor to consider.

Methane, while less efficient than hydrogen, has unexpectedly become advantageous in current circumstances.

Why Now?

The historical factor is important here. Starting with the first experiments in Germany in the late 1920s and early 1930s, engineers attempted to develop a methane engine using liquid oxygen. However, handling two cryogenic liquids (both methane and liquid oxygen require low temperatures for storage) proved too complicated. As a result, the focus shifted to simpler combinations: liquid oxygen with alcohol, or in the United States, gasoline with liquid oxygen, following Robert Goddard's example.

During World War II, both the Germans and Americans extensively experimented with liquid-fueled rockets. The Germans developed a wide range of fuel combinations, including hypergolics, while in the United States, the focus shifted to the development of JATO (jet-assisted take-off) systems to assist heavy-lift aircraft. Reliability and the ability to store fuel for long periods became major concerns, which led to the widespread use of hypergolic propellants such as hydrazine combined with nitric acid.

After the war, the experience gained led to the selection of a fuel that could be better preserved over time, as the focus shifted to armament. Due to its stability, kerosene became the preferred choice for large rockets, despite being inferior in performance to other options. The engineering of the time was largely experimental, and even switching to the more efficient hydrogen with liquid oxygen remained a challenge, particularly for smaller rocket systems.

Historically, the choice of rocket propellant has been closely tied to technological capabilities and specific mission requirements. For example, the U.S. Saturn V program used RP-1 for the first stage and liquid hydrogen for the upper stages, while the Soviet Union, facing the technological challenges of working with liquid hydrogen, stuck with RP-1. They achieved impressive results with RD-180-type engines and a multi-stage design. These decisions influenced the trajectory of rocket development during a time when reliability was the highest priority.

After gaining experience with liquid hydrogen (LH₂), the U.S. decided to pursue hydrogen as a way to increase rocket efficiency. This led to the development of vehicles like the Space Shuttle, Delta IV, and SLS. However, these are all very expensive systems that require solid fuel boosters to launch. The Delta IV Heavy, while capable of flying without boosters, is extremely costly and therefore rarely used.

Then, companies like SpaceX and Blue Origin adopted a 'First Principles' approach. SpaceX initially used RP-1 for their first rocket engine, successfully building the Falcon 9 family on well-established technology. However, the next goal for SpaceX was full reusability with multiple flights and minimal maintenance. To achieve this, SpaceX needed a more efficient fuel than hypergolics and one that was more affordable for interplanetary flights, as liquid hydrogen is difficult to store all the way to Mars, and RP-1 faces freezing challenges. Thus, SpaceX turned to methane, which is cheap, avoids these storage problems, and can even be produced on Mars. Other companies are also choosing methane for the same reason—its potential for reusability.

Interest in methane was revived decades later by innovations from Silicon Valley. Thanks to significant advances in materials science, additive manufacturing, and modeling, the old challenges of cryogenic methane storage have been addressed. Improved thermal insulation, advanced temperature control systems, and innovative design solutions now make it possible to reliably store methane in its liquid state, minimizing evaporation even during long-term storage.

Methane-powered rockets now

There’s a whole family of methane-powered rockets currently in development that you’ve likely heard of. Fewer than 10 companies are working on methane-powered rockets. However, not many know that China was the first to successfully deploy a payload into orbit using methane fuel, achieving this milestone on July 12, 2023.

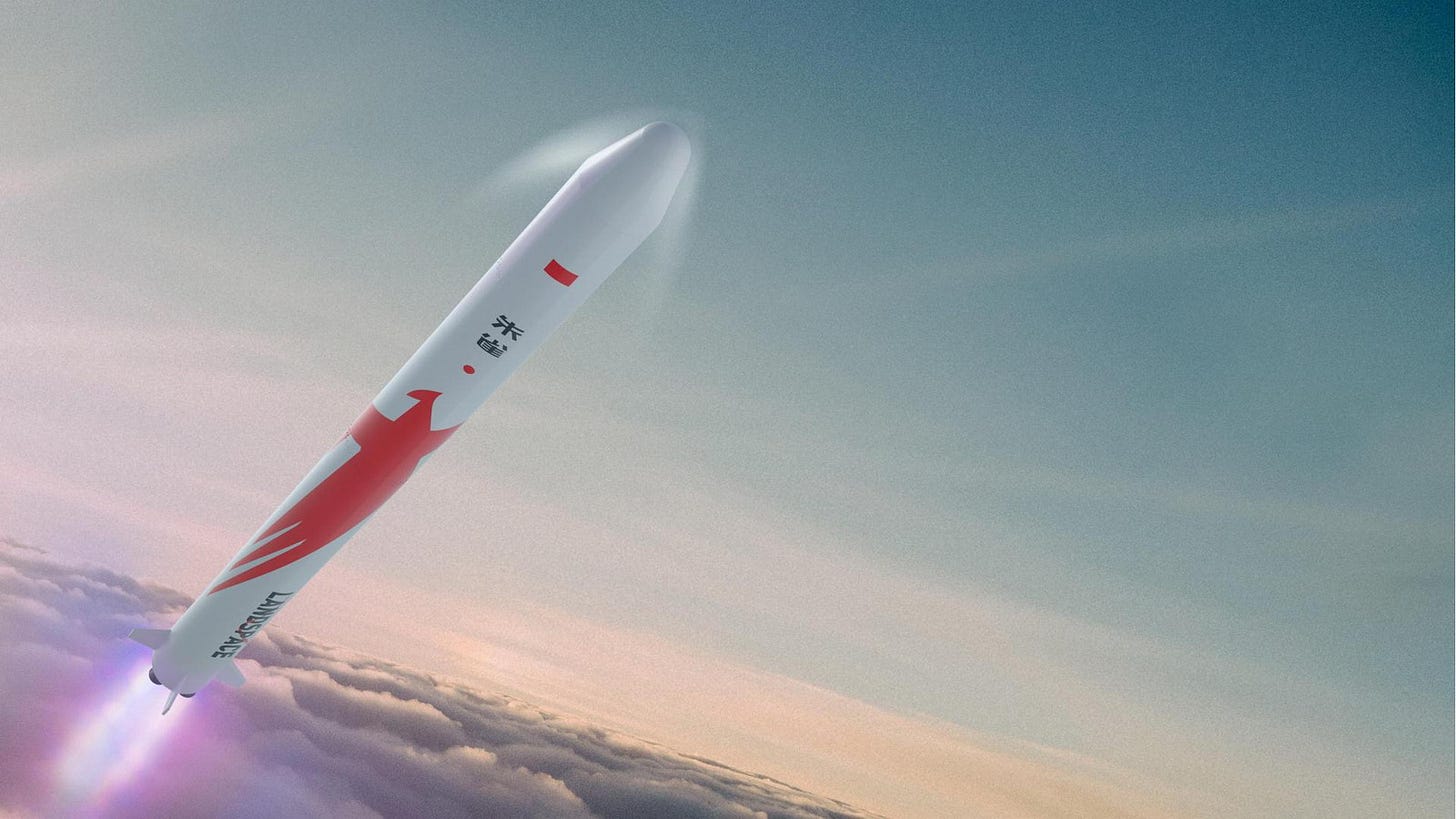

Zhuque-2 (China) by Landspace

The world's first rocket with methane was reached to orbit, which used a self-developed engine.

6 tons to LEO.

Take-off mass - 220 tons, Total Length - 47.3 m, rocket body diameter - 3.35 m.

LandSpace CEO stated that the launch cost of Zhuque-2 would be less than $7,000 per kilogram.

Since 2018 Landspace has raised $459.4 million in funding. The last series C+ round was jointly led by Sequoia Capital China, Country Garden Venture Capital, Matrix Partners China, and Cornerstone Capital. Additional investment came from the National SME Development Fund and others.

Zhuque-2 rocket. Source: Landscape

The second test launch of the Zhuque-2 on July 12, 2023, ended up with a simulated payload reaching orbit, marking the first-ever successful launch using methane as a propellant. The first real payload launch by the Zhuque-2 took place during its third launch in December 2023, where it successfully delivered three spacecraft designed for Earth remote sensing and ion propulsion testing. On November 27, 2024, an enhanced version of the Zhuque-2, capable of carrying a larger payload, was launched for the first time. This upgraded version, designated Zhuque-2E (or ZQ-2E), successfully delivered two experimental satellites into orbit.

The company is now developing the Zhuque-3 with a reusable first stage.

The rocket will be capable of launching into orbit from 12 tons in reusable mode of the rocket and up to 21.3 tonnes in expendable mode.

Successful tests have already been carried out to launch the rocket and reentry of the first stage.

The first stage is designed to be reusable at least 20 times.

LandSpace aims to reduce the cost of carrying payloads to $2,800 per kilogram, compared to $7,000 with ZhuQue-2.

The maiden launch is expected to occur during the third quarter of 2025.

The Vulcan Centaur is a heavy-lift launch vehicle developed and operated by United Launch Alliance (ULA). It is designed to replace ULA's Atlas V and Delta IV rockets. Primarily intended to meet the needs of the National Security Space Launch (NSSL) program, which supports U.S. intelligence agencies and the Department of Defense, ULA aims to price Vulcan Centaur missions competitively enough to attract commercial launches as well.

ULA began developing a new launch vehicle in 2014, primarily to compete with SpaceX's Falcon 9 and to comply with a congressional directive to phase out the Russian RD-180 engine used in the Atlas V. The first launch of Vulcan Centaur was initially scheduled for 2019 but faced multiple delays due to engine development issues.

Vulcan Centaur had a near-perfect first launch on January 8, 2024, carrying the Peregrine lunar module as part of NASA's commercial lunar cargo program. Its second launch, an NSSL certification flight on October 4, 2024, achieved an acceptable orbital re-entry, despite one of the solid rocket booster nozzles falling off, resulting in reduced asymmetric thrust.

Cost per launch - $110 million (starting)

Height - 61.6 - 67.3 m, diameter - 5.4m

Up to 27 tons on LEO

Interestingly, the rocket uses the BE-4 engine, developed by Blue Origin with some financial support from ULA. This same engine is also used on Blue Origin's New Glenn rocket.

The first launch of this rocket was originally scheduled for 2021, but after several delays, it finally took place on January 16, 2025. This mission was the first in a series of demonstration launches aimed at certification for the National Security Space Launch program.

This rocket marks Blue Origin's entry into the orbital launch market, enabling both cargo missions to orbit and the potential for sending tourists on full orbital flights. The key factor here is reusability. Like SpaceX, Blue Origin aims to make the rocket fully reusable, helping to lower launch costs.

The development and manufacturing of New Glenn are being funded by Jeff Bezos, the founder of Amazon.com, along with the U.S. Department of the Air Force. Initially financed entirely by Bezos, after 2019, New Glenn also received $500 million in funding through the United States Space Force's National Security Space Launch (NSSL) program. By September 2017, Bezos had invested $2.5 billion into New Glenn.

Project costs at least US$2.5 billion

Cost per launch US$68–110 million

Height - 98m, diameter - 7m

45,000 kg to LEO

We wrote a comprehensive article about the significance of Starship for the space market. In short, Starship has the potential to drastically reduce the cost of launching cargo into space—by up to several times (with claims stating as low as $100 per kg). Moreover, it could be the rocket that paves the way for humanity's journey to Mars.

Starship is SpaceX's only methane-powered rocket, and it’s the use of methane that plays a crucial role in this rocket's success. Methane enables full reusability of the rocket and makes it possible to generate fuel directly on Mars.

Height - 123 m

Diameter - 9 m

Payload capacity - 100 – 150 t (fully reusable)

Cost per launch - $100 million (expendable)

SpaceX primarily funds the development of Starship through private investment. SpaceX's Chief Financial Officer, Bret Johnsen, disclosed that the company has invested over $3 billion into the Starbase facility and Starship systems from July 2014 to May 2023. Elon Musk mentioned in April 2023 that SpaceX expected to spend approximately $2 billion on Starship development in 2023. In a 2024 response to a lawsuit, SpaceX stated that the cost of the Starship program was around $4 million per day.

On January 16, 2025, Starship's seventh test launch took place. The mission aimed to test new avionics systems, heat shielding, and an upgraded propulsion system, with plans to re-engage the engines in orbit. While the rocket's first stage successfully returned to the launch pad, caught by the servicing tower, the Starship itself failed to reach orbit. Instead of deploying ten mock satellites, it exploded 8.5 minutes after liftoff, with debris scattered over the Atlantic Ocean.

Elon Musk confirmed that the preliminary cause of the failure has been identified as a fuel leak, which led to a fire in the rear of the ship. According to the company's blog, the ship and booster for the next launch have already been assembled and are undergoing testing.

The ongoing development of rocket technology reflects a drive to enhance efficiency and lower the cost of space launches. Reusability has become a crucial factor in this cost reduction. The use of methane combined with liquid oxygen marks a new stage in this evolution, offering an optimal balance between performance, compact fuel systems, and reusability. This approach not only improves engine performance but also opens up possibilities for interplanetary missions, such as the colonization of Mars.

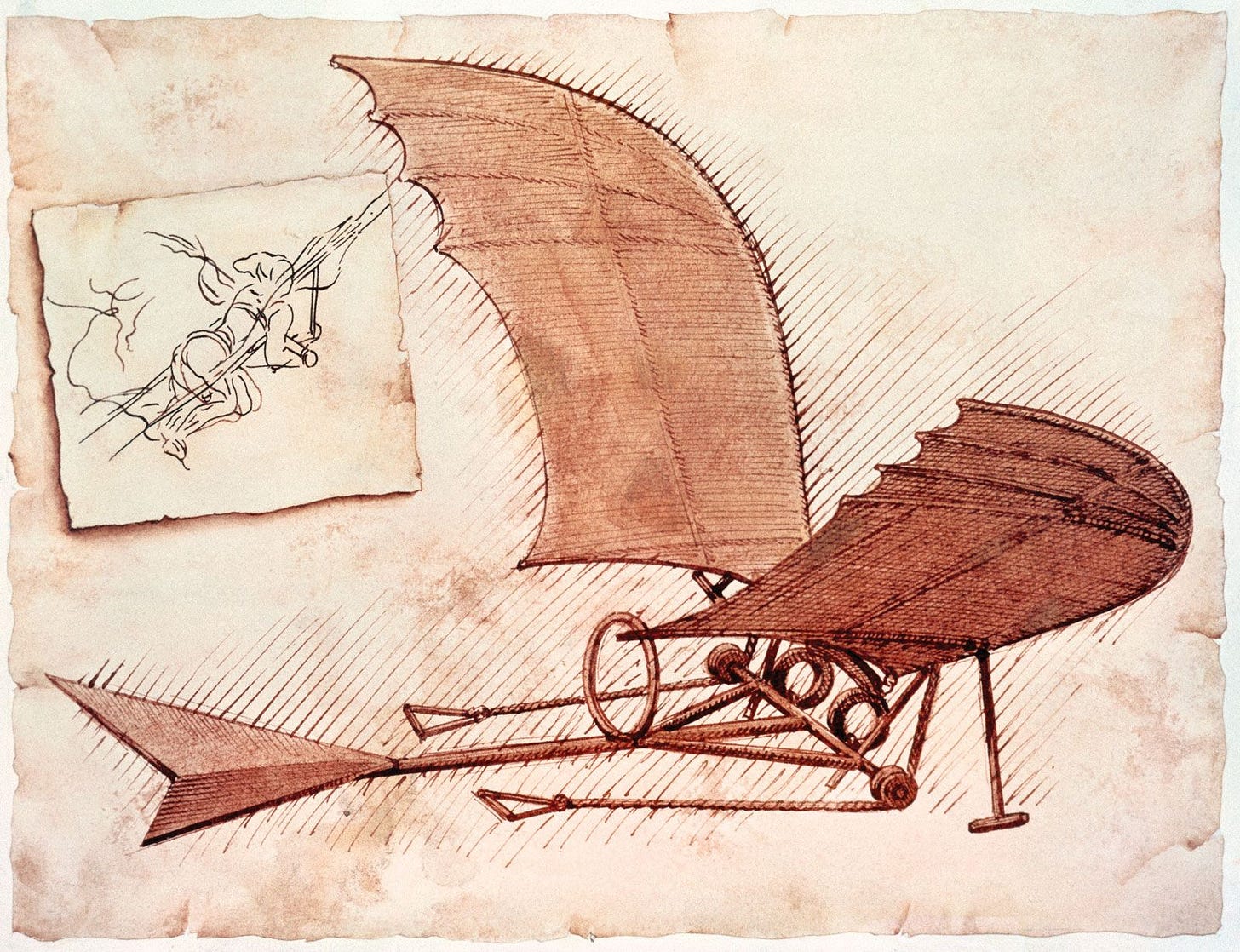

It’s fascinating how the idea of using methane as a fuel, which is not new, has only recently found its application and relevance. This mirrors the early concept of airplanes, first proposed by Leonardo da Vinci—hundreds of years passed before the right technologies were developed. Each new development and test mission serves as a reminder that the future of space is shaped by bold ideas, perseverance, and an unwavering belief in the impossible. At Space Ambition, we believe there are no bad technologies, and every idea will find its place when the time is right.

Details of the fuel efficiency table calculations from the article:

(1) Specific impulse values are provided for the following engines, all operating in a vacuum: LH2: RL10B-2 (Delta IV); Methane: Raptor 3 Vacuum (Starship); and RP-1: Merlin 1D Vacuum (Falcon 9 Block 5).(2) We assume the methane (CH4) is refined and free of impurities. Kerosene, being a mixture of various hydrocarbons, predominantly alkanes, is modeled here as dodecane (C12H26), which is a reasonable simplification.

(3) We are modeling only direct CO2 emissions in this analysis. Indirect CO2-equivalent emissions, such as uncombusted hydrocarbons (primarily CH4), NOx, and emissions from chemical processing, compression, and transportation, are not considered. The formula used to calculate CO2 per unit of impulse, assuming stoichiometric combustion, is the following: CO2/impulse = m(CO2)/((m(fuel)+m(LOX)*u), where u is the specific impulse in m/s. This assumption introduces only a slight deviation from real-world conditions. For instance, while stoichiometric methane combustion theoretically requires a mass ratio of 1:4 (CH4 to O2), the Raptor engine uses a ratio of approximately 1:3.6, which is quite similar. Although stoichiometric combustion maximizes thermal energy release, shifting to a non-stoichiometric ratio is optimal for efficient thermal-to-mechanical energy transfer.

(4) The indicated prices for hydrogen, methane, and RP-1 are for unrefined products. We believe these represent optimistic lower bounds for refined products, assuming mass production is stimulated by frequent rocket launches. These prices are also comparable to (or even higher than) Elon Musk’s estimates. The current prices for rocket-grade RP-1 and LOX can be found here.

(5) The propellant cost per unit of impulse is calculated using the following formula, assuming stoichiometric combustion: cost/impulse = (price(fuel)*m(fuel)+price(LOX)*m(LOX))/((m(fuel)+m(LOX)*u), where u is the specific impulse in m/s.

Met a guy from a space startup who builds paraffin engines and claims they cut costs by half. Any insights on that?