How to Build a Satellite: A Comprehensive Guide

The number of satellites in space is rapidly increasing, and building them is becoming more accessible. This article provides a concise guide on how to build a satellite.

Issue 83. Subscribers 11 230.

Unlock exclusive access to our handpicked selection of top deep tech investment syndicates, premier space conferences, and a comprehensive list of space investors and accelerators. More information here.

Satellites have become an indispensable part of the modern space industry. Currently, there are over 10,000 active satellites in orbit, and their numbers are rapidly increasing each year. One key reason for this growth is that developing and building satellites is becoming progressively easier.

In December 2023, our co-founder Marat Airapetian, as part of a dedicated team, launched the first Armenian domestic satellite. He will share his first-hand experience in developing a satellite. This article will cover what a satellite is, how it is designed, and how it is tested.

The general phases of satellite development are as follows:

Set goals and objectives, formulate requirements for the system.

Select orbit and payload.

Select suitable components for the required payload.

Order and purchase components, await their arrival.

Start the regulatory approval process.

Receive the components, test them and assemble the ground mock-up of the satellite.

Find a clean room and build the flight version.

Test the flight version of the satellite .

Send it to the launch site (or to brokers for additional testing).

Prepare the Mission Control Centre and wait for launch.

Let's go through each of these steps.

Do I Really Need a Satellite?

Previously, it was thought that every space startup or company should have its own satellites. However, now there are many companies that provide space services without owning their own satellites. For example, they can process and sell satellite images.

For instance, if your task is image processing or you have a unique instrument, you can make use of existing satellites. You can purchase ready-made photographs from existing satellites and build your own constellation in the future.

If you have developed a payload for a satellite or a space instrument, the situation is similar. There are companies that provide space on their spacecraft to host the payload. It is important to decide whether you will build the payload and satellite elements yourself or buy them from other companies. The budget of your mission will depend on this decision - It's more expensive to develop satellite components yourself.

When starting the design process, it is important to answer the following key questions:

What are the goals and objectives of the mission?

Do I need a satellite to accomplish this mission?

Is one satellite sufficient or do I need more than one?

What payloads will be installed on the satellite?

Which components will I build myself and which ones will I purchase from outside manufacturers?

Once you have defined the goals and objectives of your mission, you need to select the payload and orbit of the spacecraft. This is always a challenging and exciting process.

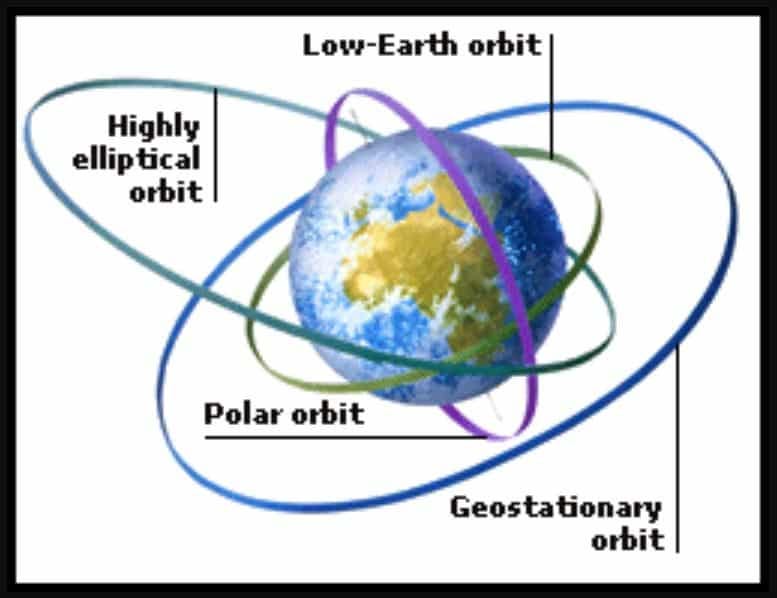

For example, if you are developing a satellite for Earth observations, you may choose a lower orbit (~400 km). In this case, you can use a camera with less powerful characteristics. Conversely, the higher the orbit, the more powerful the camera should be. The following factors usually influence the choice of orbit:

Revisit time of the area of interest.

Duration of the satellite's communication session with the ground station to maximize downlink.

Payload parameters.

The chosen orbit parameters and payload specifications will serve as the input data for further development.

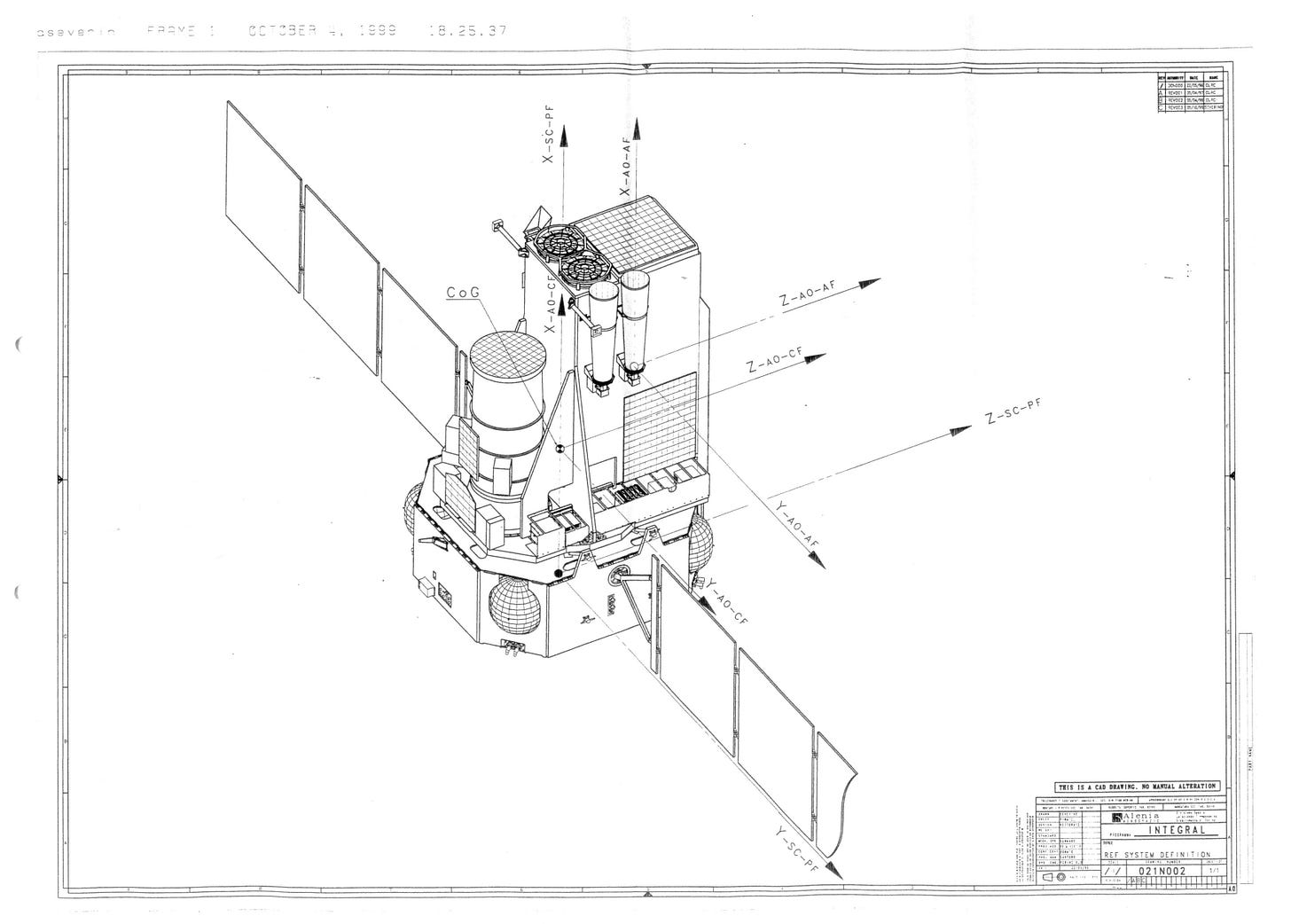

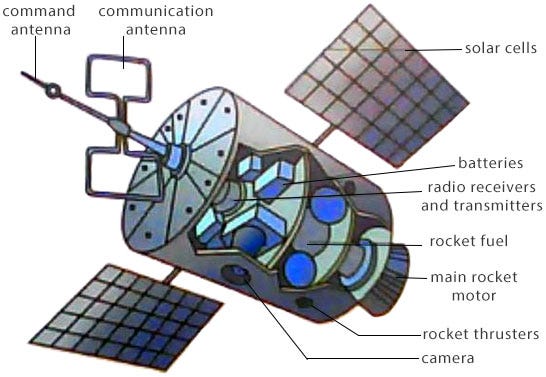

A satellite can be divided into two main components: the bus and the payload. Imagine a car whose purpose is to transport people. All the systems of the car are designed to fulfill this task. It is similar for a satellite: the bus represents the main systems of the satellite that ensure the functioning of the payload.

What Does a Satellite Consist Of?

The bus typically includes the following key components:

On-board computer: the «brain» of the system, which distributes tasks to other subsystems, sends commands and makes necessary calculations.

Electric power system: which includes a combination of Batteries and solar panels. It is responsible for distributing electricity to the subsystems and recharging the batteries.

Communication system: which provides communication sessions with the Earth. It most often includes an antenna and is responsible for receiving commands and data from Earth and transmitting the data back to Earth.

Control system: which is responsible for everything related to the flight Trajectory. Includes the controls (engines, magnetic coils, reaction wheels) to control the rotation of the vehicle around its axis and change the orbital position. Often this unit also includes the navigation system (GPS orbit determination and determination of the angular position of the vehicle).

Payload and support systems perform specific mission tasks, such as photography, scientific data collection or communications.

An important element of a satellite is the development of the ground segment — the station for receiving data and sending commands with the Mission Control Center. Here, again, you have the choice of building your own station or renting one.

Component Selection Dilemma

Of course, an important question is which of the components of the satellite you want to develop yourself and which ones you want to buy. As technology progresses, suppliers are becoming more numerous and satellites are becoming easier to assemble. Even schools are building satellites now. You can buy components from companies, for example: Reflex Aerospace GmbH, EnduroSat, XDLINX LABS and to order an off-the-shelf satellite from Satlantis.

Buying ready-made components for satellites and integrating them into a single system is not a simple task. It requires a lot of effort on the part of developers, so make sure you have strong specialists in your team. Especially for the first missions, it is recommended to use the customer support service from the hardware manufacturers. This can significantly reduce development time and future problems for your developers.

In parallel with the process of developing the core systems, it is crucial to pay attention to planning launch and legal aspects. First of all, after preliminary calculation of the mass of the vehicle, it is necessary to deal with the issue of launch into orbit. Often launch sites are booked in advance, and the launch to the orbit you want does not happen every day. Therefore, it is important to plan this process in advance.

In such cases, they often turn to brokers. This is similar to the situation when we order a cab: we don't contact cab drivers directly, but go to Uber or another similar company, which finds us the nearest driver. With satellite launches, the situation is similar — you can contact a broker company such as (Precious Payload, ISISpace) to launch your device. In addition, brokers provide important services such as technical support and testing of the satellite (more about this later).

We will write a big article about the sattelite components, the available market and brokers of such services.

Legal Aspects

On the other hand, it is very important to get all the necessary launch authorizations. For small satellites, at a minimum, you need to obtain authorization from the International Telecommunication Union (ITU).

The ITU manages a cooperative system for international coordination of radio frequencies used by satellites. This system aims to prevent such systems from interfering with each other or with other radio systems. The ITU oversees the process of registering satellite frequencies, during which an ITU Member State submits a description of the radio frequencies planned to be used in a project by its satellite operators.

Also, if you are launching a vehicle for the first time, you need to meet the requirements of your country. Often, you need to obtain a license for space activities, which could take up to several months.

Most Careful Process - Assembly

After you have received the equipment - the most careful process begins - assembly and testing of the satellite.

First of all, it is necessary to make sure that all received components correspond to the declared parameters and work correctly. This is an important stage that will simplify the search for problems in the future and avoid defective parts.

Typically (especially for small satellites), two copies of the satellite are built. The first one is a test ground copy. All procedures, especially assembly and testing, are first practiced on it. It will later be used as a ground model to check the operation of systems if something goes wrong in space. The second model is a flight model. It is assembled in a clean room using proven procedures. A clean room is a space where the air contains a certain amount of dust particles, micro-organisms, aerosol particles and chemical vapors per cubic meter. Dust and other contaminants can adversely affect the microelectronics of the machine. This clean room can be rented or built, especially if you plan to build satellites in the future.

The next step is to establish a procedure for assembling and testing the vehicle. As the satellite is a complex technical device, it can be dangerous to simply assemble it and switch it on, and it is difficult to detect errors in operation. It is therefore important to start testing as soon as the first components are assembled.

For example, you can connect the on-board computer and the power system and check how they work together. Then add the solar panels and make sure they charge the battery. And so on. Precision and thoroughness are important. Don't forget to work out how the whole satellite interacts with your ground station!

Simulate Space on Earth - Environmental Tests

Once you assemble the satellite and check the components you will need to run a number of tests.

Vibration test. When the rocket launches, the satellite is subjected to severe vibration. It is necessary to check that the instrument can withstand these stresses. This is done by placing it on a stand and subjecting it to vibrations at the same frequency as the rocket's launch.

Thermo-vacuum tests in an environment. These chambers simulate the environment in space: vacuum and temperature variations. The satellite is placed in a chamber with vacuum and simulated heating by the sun and cooling in the shade.

Other test for big satellites: Electromagnetic compatibility test, antenna pattern test etc.

The next step is to clear customs and ship the satellite to the launch site. This is usually the most pleasant part - when the work has already been completed. Typically, the satellite is sent to the spaceport 3-4 months before launch.

Often the brokers (mentioned above) will carry out additional tests to satisfy the launch vehicle suppliers.

Mission Control Center

Once the satellite has been sent to the launch site, it is time to prepare the Mission Control Centre. You need to set up data transfer from the station to the operators' computers, prepare operator procedures, etc. The task of operators is to check all satellite systems, receive data from payloads, and send commands. Depending on the task, your operators may be in the Mission Control Centre all the time, or they may come in as information is received and transmitted. Often this process is automated and no human is needed at all.

At the same time, we should be working on public relations - preparing a PR plan, finding contacts and informing the media about the upcoming launch. Check out our space PR articles here and here.

Of course, this description is suitable for small satellites and cubesats. Some items may be added, swapped or reduced. The development of a large satellite differs in that it usually involves the development of unique components, the creation of only one version of the satellite (only the flight version, two versions are too expensive to build), and more thorough testing.

We've written a pretty detailed and technical manual to help you understand the details. In fact - nowadays even schoolchildren have mastered the process of satellite assembly due to the simplification of technology. Most of the work can be outsourced - all that is left to do is to connect all the parts and program them.

Technology is not standing still. It is getting easier and easier to assemble and launch satellites into space. Cubesat technologies have made a huge contribution to this. We believe that as more and more satellites become available and easier to build, more and more of the services we use every day on Earth will be created. Who knows, maybe our kids will be building satellites at schools on a regular basis in the near future!

If you're planning a project and don't know if you need your own satellite, or if you've encountered difficulties in building your vehicle, drop us a line via hello@spaceambition.org! We will be happy to help!

Small remark, if I may. Reflex Aerospace does not sell the components. We design and build the satellites tailored to our customers requirements.

We take an approach of gradual verticalization of supply chain, starting from building our own on-board computer.

Thank you for mentioning us though!

Also, another small remark - you are missing the ground segment of the system, so your MCC would work.